How to win friends and influence people: the Wilton Park method

Wilton Park Voice

We provide a space where ideas are tested and accelerated, and new projects and policies are born.

What we doWe curate events that harness the expert knowledge of participants to facilitate insightful discussions and grow networks of influence.

Latest events

We bring together those with decades of experience with the leaders and decision makers of tomorrow, convening the right people at the right time, for conversations that move agendas forward and solve problems.

Get involved

How to win friends and influence people: the Wilton Park method

Wilton Park Voice

Building relationships to build trust

Wilton Park Voice

Promoting the Sustainable Development Goals (SDGs), Climate change and the environment

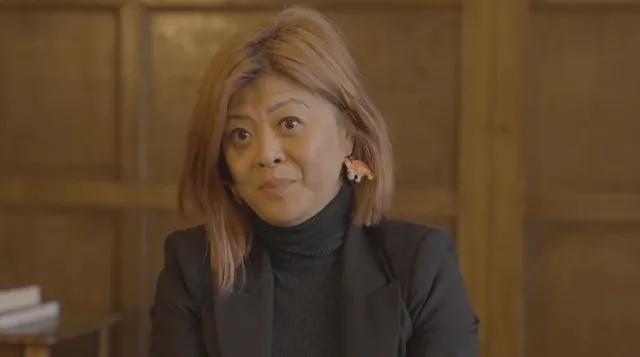

Women’s rights organisations and movements in crises – video playlist

Watch

Women and girls

We get the right people in the room and facilitate dialogue that’s influential in addressing the world’s most pressing challenges.

Partner with usSince our inception we have always undertaken important and challenging work. From rehabilitating prisoners of war following World War II, facilitating conversations about the end of apartheid, to bringing together opposition groups after the Balkans war, we have gripped issues when others hesitate.

More about our history